Industrial-Grade Animal Fat Primary Rendering

Explore More-

Centrifuge

-

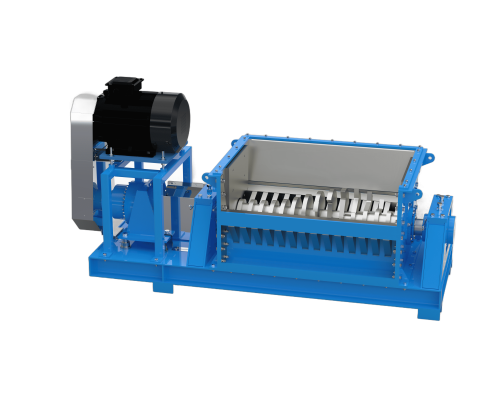

Feed Grade Crusher

-

Cyclone

-

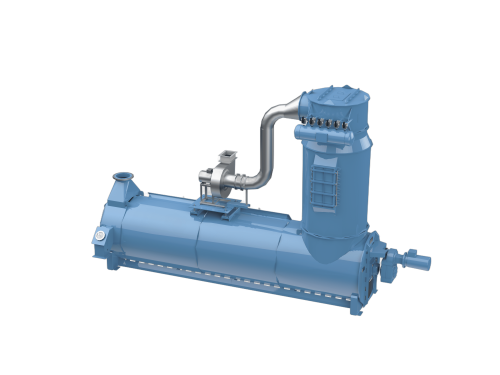

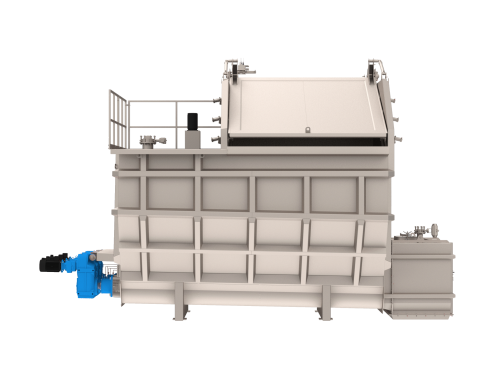

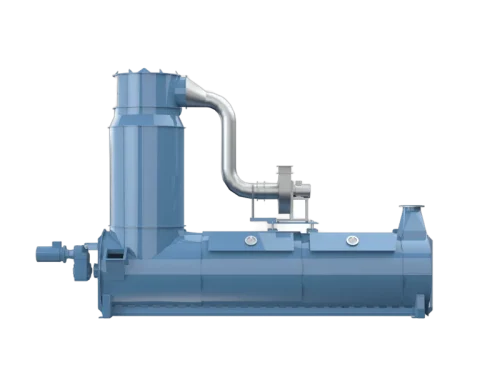

Disc Dryer

-

Fat Filtrator

-

Fat Press

-

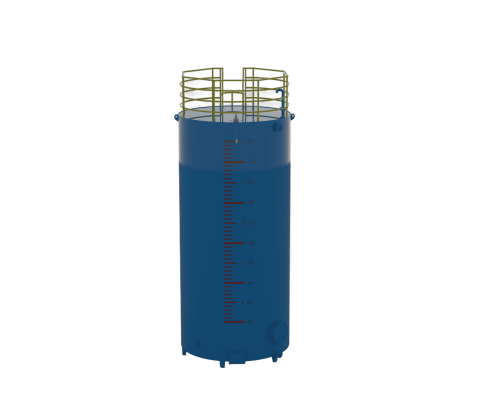

Finished Oil Storage Tank

-

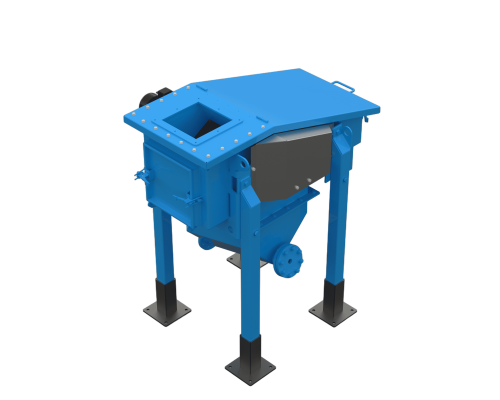

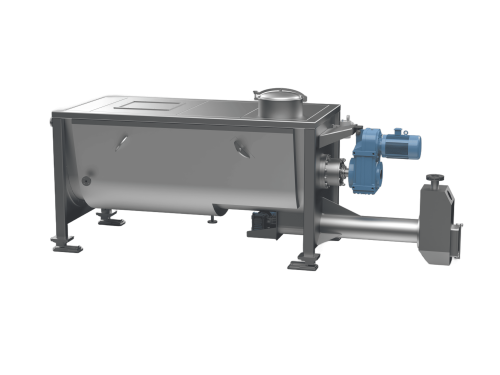

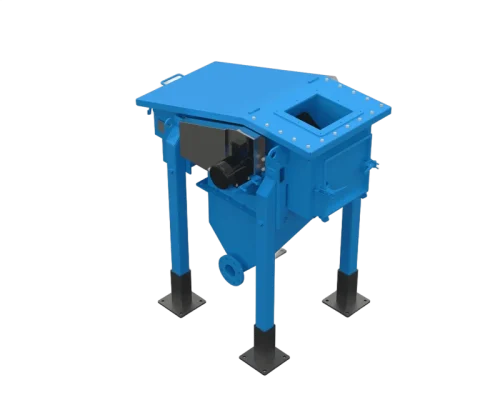

Material Bin

-

Milling Plant

-

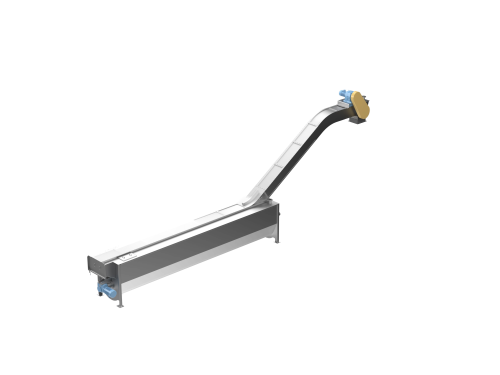

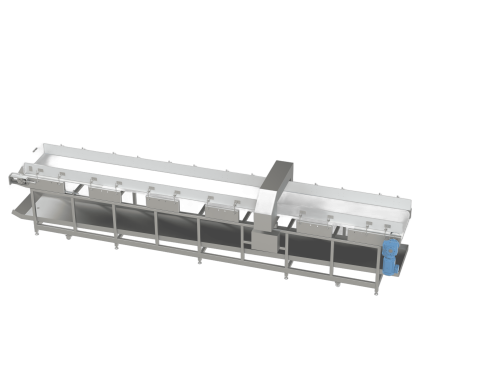

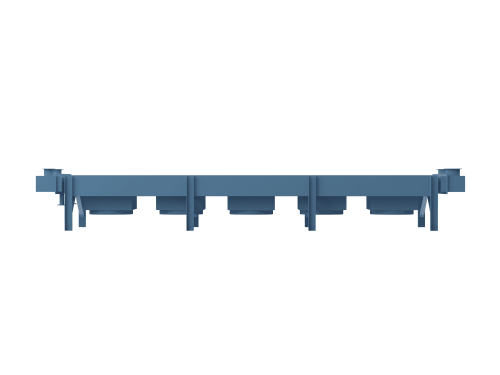

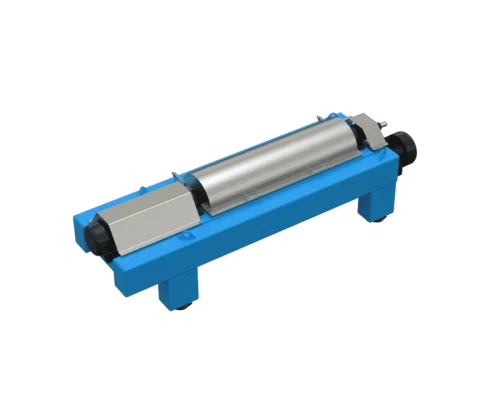

Meal Cooling

-

Scrubber

-

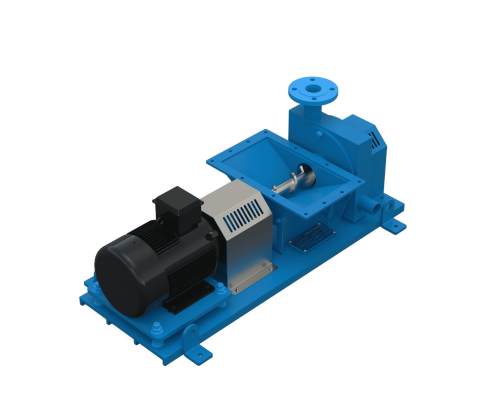

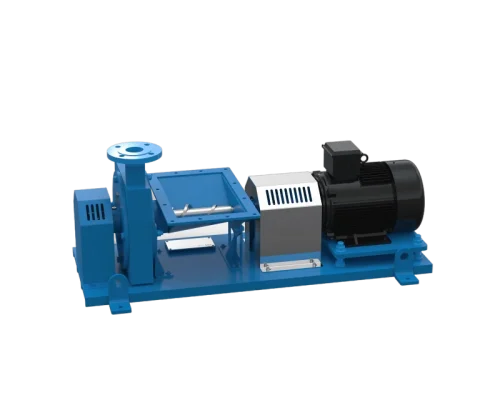

Oil Pump

-

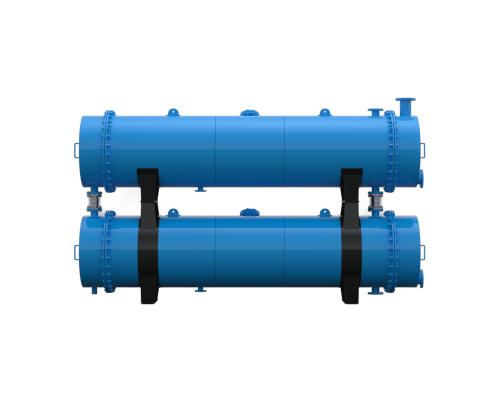

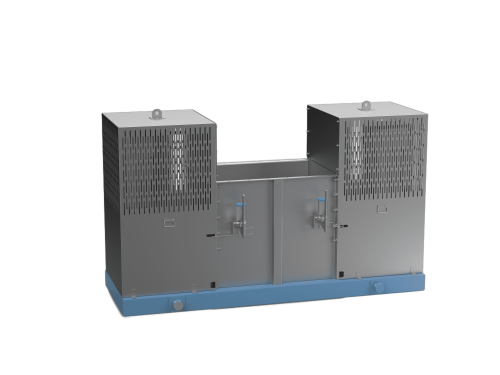

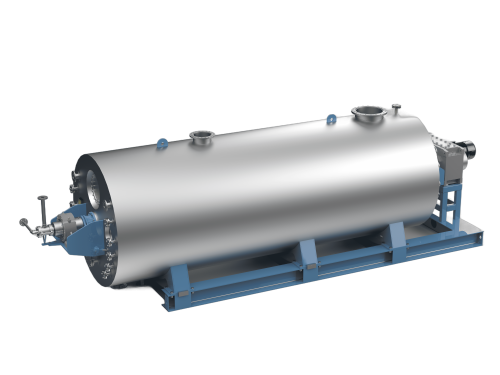

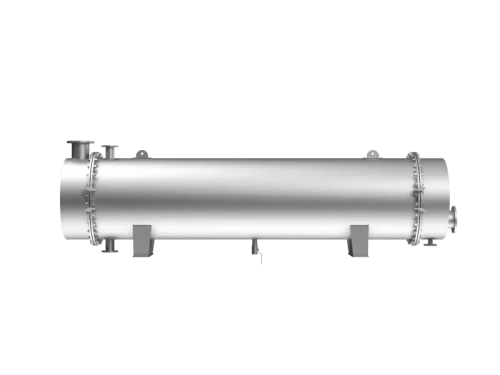

Condenser

-

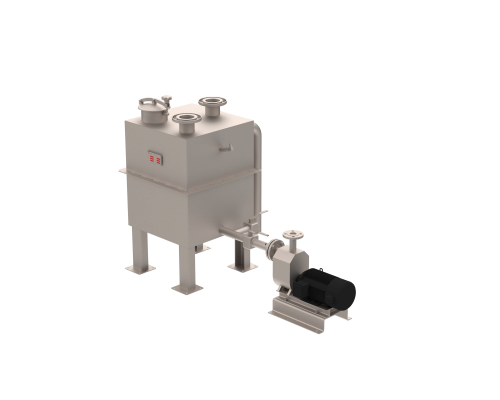

Heating Buffer Tank

-

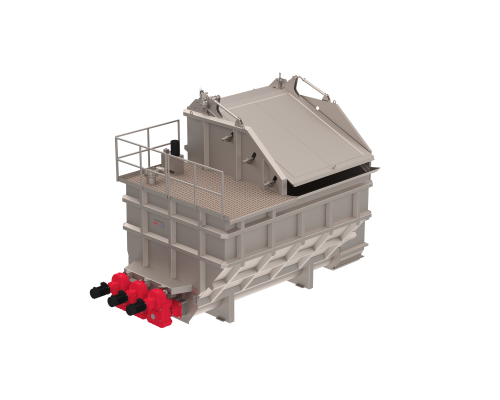

Meat Scraps Storage Bin

Food-Grade Animal Fat Primary Rendering

Explore More