In the poultry processing industry, chicken rendering plays a crucial role in converting waste materials into valuable products like animal feed, biofuels, and premium chicken fat. A well-designed chicken rendering plant not only improves efficiency but also enhances the recovery of high-quality chicken fat.

In this article, we will explore how a high-efficiency chicken rendering plant maximizes chicken fat recovery through optimized processes and cutting-edge equipment.

The Importance of Chicken Rendering

Chicken rendering is the process of converting chicken by-products, including feathers, skin, bones, and fat, into usable forms. The rendering process is vital for creating a sustainable, environmentally friendly solution for waste disposal while also producing high-value products. Among these, premium chicken fat is in high demand due to its excellent properties as an ingredient in animal feed and other commercial applications.

A high-efficiency chicken rendering plant utilizes advanced technologies to improve the yield and quality of chicken fat. By maximizing the recovery rate of chicken fat, poultry processors can not only reduce waste but also significantly increase profitability.

Key Components of a High-Efficiency Chicken Rendering Plant

To achieve optimal performance in chicken fat recovery, a chicken rendering plant integrates several specialized components designed to handle the various stages of the rendering process:

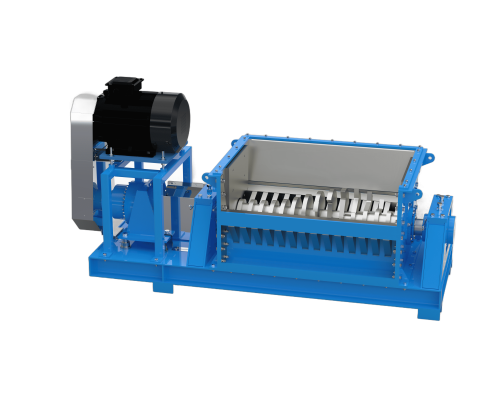

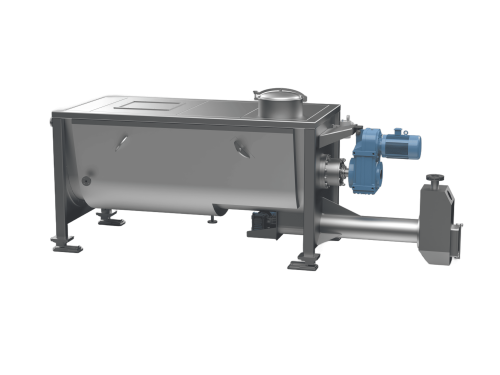

Animal Rendering Pre-Crusher

The rendering process begins with the Crushing Unit (or Size-Reduction Module), which efficiently breaks down chicken by-products into smaller particles. This step is crucial for increasing surface area, allowing for better fat extraction.

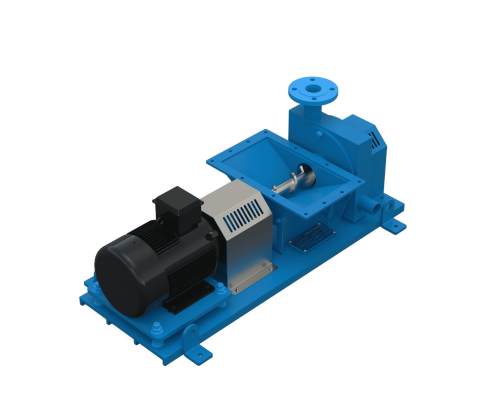

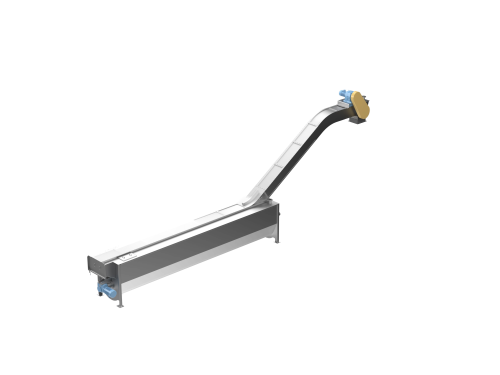

Fat-Transfer Conveyors & Pumps

After the by-products are processed, Fat Transfer Pumps move the rendered fat through the system. These pumps are designed to handle the viscous nature of the fat, ensuring smooth transfer to the next stages of the process. Vane Pumps and Metal-Detection Conveyors are incorporated to guarantee that the fat is pure and free from any metal contaminants.

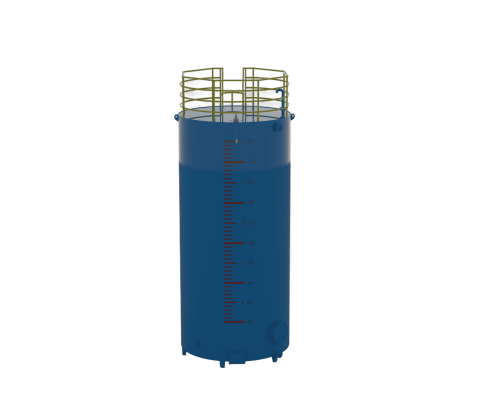

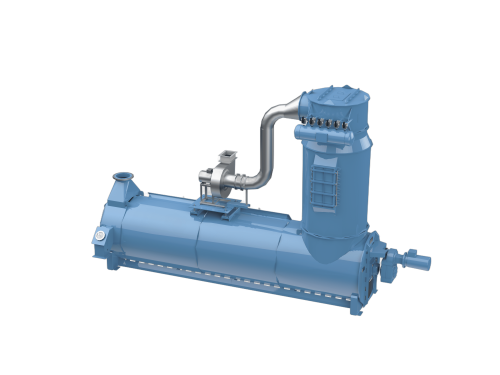

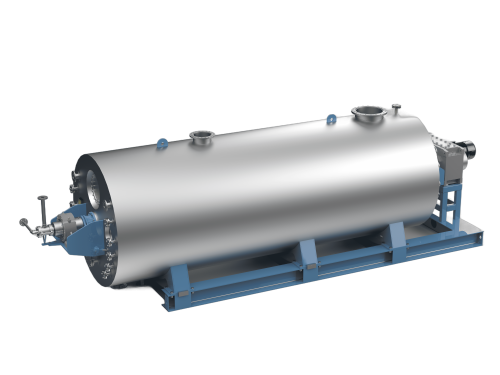

Fat cooker

Clean raw materials will enter the smelting kettle for negative pressure oil refining, resulting in crude animal oil and solid oil residue.

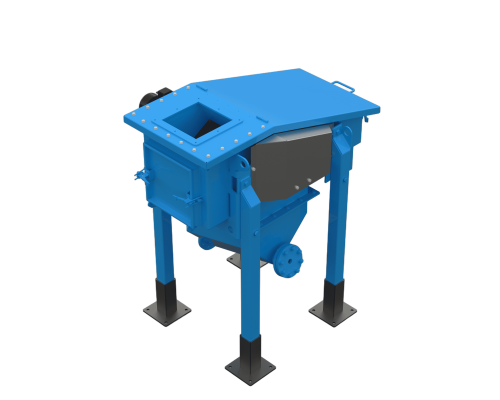

Fat Pressing Equipment

The rendered fat residue is then subjected to Screw Fat Press Machines, which further squeeze out any remaining fat from the solid material. This step helps to maximize the recovery rate and ensure that the final product has the highest possible quality.

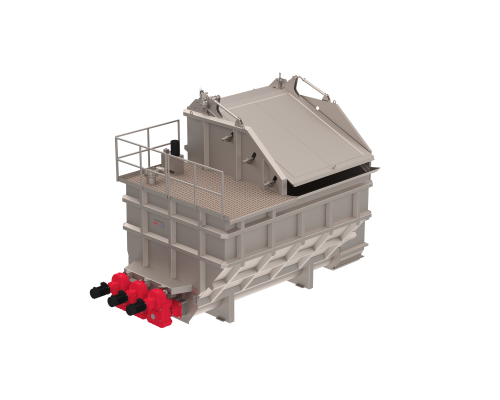

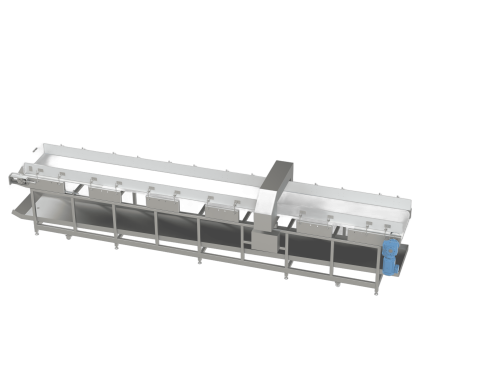

Rendering Plant Separation

Continuous Horizontal Centrifuges are used to separate the fat from any remaining solids. This equipment efficiently separates fats, oils, and water, ensuring the purest form of chicken fat is recovered. Fat Vibratory Screens also help in filtering out unwanted particles, making sure that only high-quality chicken fat is retained.

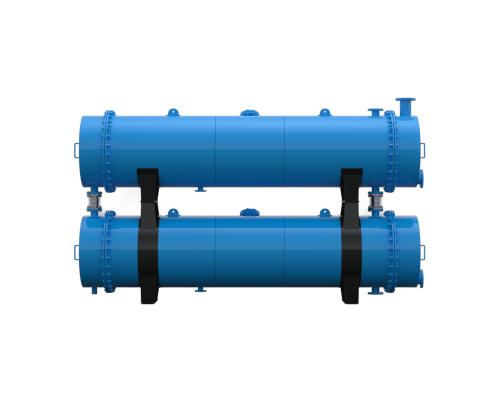

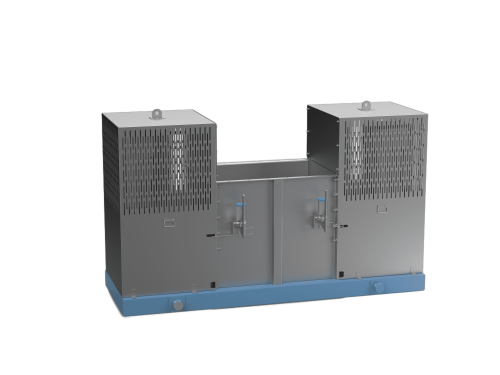

Cooling & Condensing Equipment

Meal Coolers are used to lower the temperature of meat-and-bone meal after rendering, ensuring safe handling and stable quality. Shell and Tube Condensers condense process steam and exhaust gases generated during rendering and drying, improving energy efficiency and waste-gas treatment.

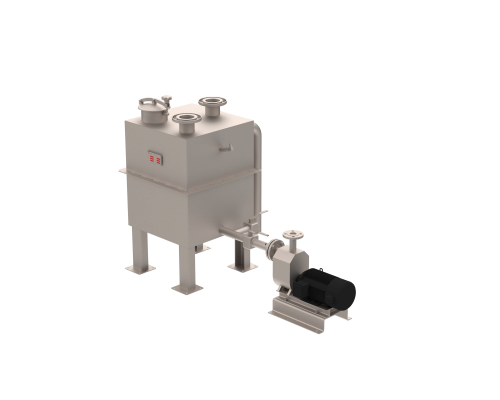

Waste Gas Treatment

Wet Scrubber Towers and Cyclone Dust Separators are installed to capture and neutralize waste gases generated during the rendering process. These systems ensure that the plant operates within environmental regulations and contributes to a cleaner and more sustainable operation.

Maximizing Premium Chicken Fat Recovery

A high-efficiency chicken rendering plant focuses on maximizing the recovery of premium chicken fat through various means:

Optimized Equipment Design

Using equipment such as Screw Fat Press Machines and Continuous Horizontal Centrifuges ensures that the fat extraction process is as efficient as possible. Each component is designed to minimize waste and maximize fat recovery, making it possible to extract every last drop of valuable chicken fat.

Advanced Separation Techniques

The combination of Fat Vibratory Screens and Metal-Detection Conveyors ensures that the extracted fat is free from contaminants. By employing advanced separation technologies, the plant can provide a pure and high-quality product.

Energy Efficiency

A high-efficiency chicken rendering plant is designed to operate with minimal energy consumption. Through advanced control systems and efficient pumps, the plant minimizes energy waste, reducing operational costs while maintaining high fat recovery rates.

Continuous Monitoring and Control

Modern vacuum pump stations and advanced control systems allow for real-time monitoring and optimization of the rendering process. By adjusting parameters such as pressure, temperature, and flow rates, the plant can ensure that the fat recovery process is running at peak efficiency.

Benefits of High-Efficiency Chicken Rendering Plants

- Increased Profitability: Maximizing fat recovery leads to higher product yield, directly impacting the profitability of poultry processing operations.

- Environmental Benefits: The rendering process helps reduce waste and converts by-products into useful products, contributing to a more sustainable business model.

- High-Quality Products: By using advanced technologies, the plant ensures that the recovered chicken fat is of premium quality, suitable for high-end applications in the animal feed and industrial sectors.

- Regulatory Compliance: Modern rendering plants are equipped with wet scrubber towers and cyclone dust separators, ensuring compliance with environmental regulations by reducing harmful emissions.

Applications and Economic Benefits: Versatile Uses of Premium Chicken Fat

A chicken rendering plant serves several critical functions in modern poultry processing. The recovered fat is then processed and refined for use in various industrial applications, including:

Animal Feed Production

The premium chicken fat and meat meal produced in rendering plants are essential ingredients for high-quality animal feed. These by-products offer valuable nutrients that support the growth and health of livestock.

Biofuel Production

Rendered chicken fat is a sustainable feedstock for biodiesel production. Its high energy content makes it an ideal material for renewable biofuels, contributing to greener energy solutions.

Pet Food Manufacturing

The high-quality rendered proteins and fats are widely used in the production of premium pet foods. They provide essential nutrients, ensuring a healthy and balanced diet for pets.

Conclusion

A high-efficiency chicken rendering plant maximizes chicken fat recovery through state-of-the-art equipment and optimized processes. By focusing on fat extraction, waste reduction, and energy efficiency, poultry processors can boost profitability and contribute to a more sustainable operation. With the increasing demand for high-quality chicken fat in various industries, investing in a well-designed rendering plant is an excellent way to meet both economic and environmental goals.